Behind the Scenes: How Custom Moulded Brass Plaques Are Made

If you’ve ever strolled through a beautiful park, admired a grand building, or visited a memorial site, chances are you’ve spotted a gleaming brass plaque. These little works of art don’t just pop out of thin air—they’re the result of centuries-old craftsmanship and some seriously cool science. Whether you’re searching for “the best trophy store Adelaide” or just curious about how those shiny memorial plaques come to life, you’re in for a treat! Let evright take you through the process!

So, how do custom moulded brass plaques go from a simple idea to a polished plate that stands the test of time? Let’s take a behind-the-scenes tour of the fascinating process, from raw materials to the proud moment your plaque is unveiled.

Step 1: Dream It, Design It

Every custom plaque starts with a story. Maybe it’s a memorial plaque to honour a loved one, a plate for a historic building, or a trophy for the local footy champs. The first step is all about capturing your message and vision. At evright.com, our design team works closely with you to create the perfect look—whether you want classic elegance, bold modern flair, or something totally unique.

We use the latest design software to turn your ideas into a digital masterpiece. You’ll see a proof before we get started, so you know your custom plaque will be exactly what you want.

Step 2: Crafting the Mould – Where Laser Engraving Magic Begins

Here’s where things get old-school. To create a moulded brass plaque, we need a mould—a negative impression of your design. Think of it as the plaque’s “cookie cutter,” but way fancier.

There are a few traditional methods for mould-making, each suited to different plaque styles:

A. Wood Moulds

For intricate, raised designs, we often use carved wood. Skilled artisans (yes, we have a few wizards on staff) carve your design into a block of hardwood. Every letter, logo, and flourish is shaped by our quality laser engraving process. This wooden mould will become the master for your plaque.

B. Sand Casting Moulds

For larger or more textured plaques, sand casting is the go-to method. Here’s how it works:

Step 1: A pattern of your plaque is made, usually from wood or resin.

Step 2: The pattern is pressed into a special sand mixture inside a frame, leaving a perfect imprint.

Step 3: The pattern is removed, and the sand holds its shape, forming a cavity ready for molten brass.

Sand casting is as much about science as it is about artistry—the sand needs to be just the right mix of fine and coarse, damp but not too wet, to hold the details of your custom plaque.

Step 3: Pouring the Brass for The Brass Plaque – The Fiery Finale

Once the mould is ready, it’s time for the real showstopper: pouring the brass. Brass is an alloy made of copper and zinc, prized for its golden glow, durability, and resistance to corrosion (take that, weather!).

Melting: Brass ingots are heated in a furnace until they reach a fiery 900°C+ (that’s hotter than a summer day in Adelaide!).

Pouring: The molten brass is carefully poured into the sand or wood mould. This is a moment that combines nerves of steel and a steady hand—one wrong move and it’s back to square one.

Cooling: The filled mould is left to cool and solidify. As it cools, the brass takes on every detail of your design, from the tiniest letters to the grandest crests.

Step 4: The Big Reveal – Breaking the Mould

Once cooled, the mould is carefully broken open to reveal the new plaque. This is always a moment of excitement—kind of like unwrapping a present, but with more sand and a lot more pride.

Cleaning: The plaque is cleaned to remove any sand or wood residue.

Trimming: Edges are trimmed and smoothed, and any excess metal is removed.

Polishing: The surface is polished to a high shine, or given a brushed or antique finish, depending on your style.

Step 5: The Finishing Touches

Your plaque is almost ready for its close-up! Now it’s time for the details that make it truly custom:

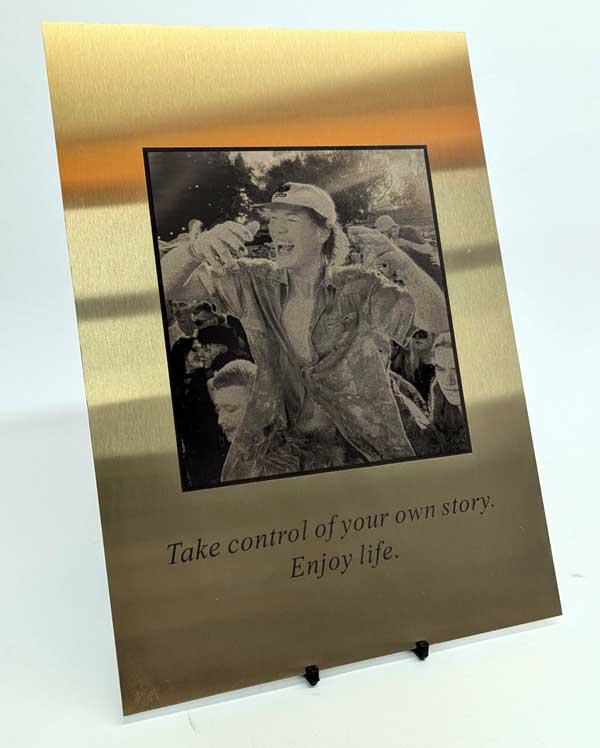

Laser Engraving: For extra personalization, details can be laser-engraved onto the brass plaque. This is perfect for adding names, dates, or messages to memorial plaques and plates.

Painting: Some plaques feature paint-filled lettering for extra contrast and flair.

Mounting: Holes can be drilled for easy installation, or special mounts can be added for display.

Step 6: Quality Check and Delivery

Before your plaque leaves our workshop, it goes through a rigorous quality check. We make sure every detail is perfect—because nothing less will do for our customers!

Your finished custom plaque is then carefully packed and shipped, ready to take pride of place wherever it’s needed.

Why Choose Moulded Brass Plaques?

Brass plaques aren’t just beautiful—they’re built to last. They resist tarnish, withstand the elements, and develop a gorgeous patina over time. Whether you’re honouring a hero, marking a milestone, or branding your business, a custom brass plaque is a lasting tribute.

And if you want something different, don’t worry—we also offer stainless steel plaques, acrylic plates, and a huge range of trophies and awards. (Just search “trophy store near me” and you’ll find evright at the top of the list!)

Which Plaque Is Right for You?

- Memorial Plaques: Honour loved ones or celebrate achievements.

- Plates: Perfect for doors, desks, and display cases.

- Moulded Brass Plaques: For a classic, timeless look.

- Stainless Steel Plaques: Modern and super-durable.

- Custom Plaques: If you can dream it, we can make it!

Ready to Make Your Mark?

If you’re searching for the “best trophy store Adelaide” or need a custom plaque for any occasion, evright.com is your go-to. With decades of experience, a team of passionate craftspeople, and a playful approach to every project, we make the process as memorable as the plaque itself. Drop by our store, give us a call, or browse our huge range online.

Whether you need one plaque or a hundred trophies, we’re here to help you celebrate, commemorate, and shine.Want to see the magic in action? Visit us at evright.com or pop “trophy store near me” into your search bar and let’s create something amazing together!

Contact us for your plaque quote today